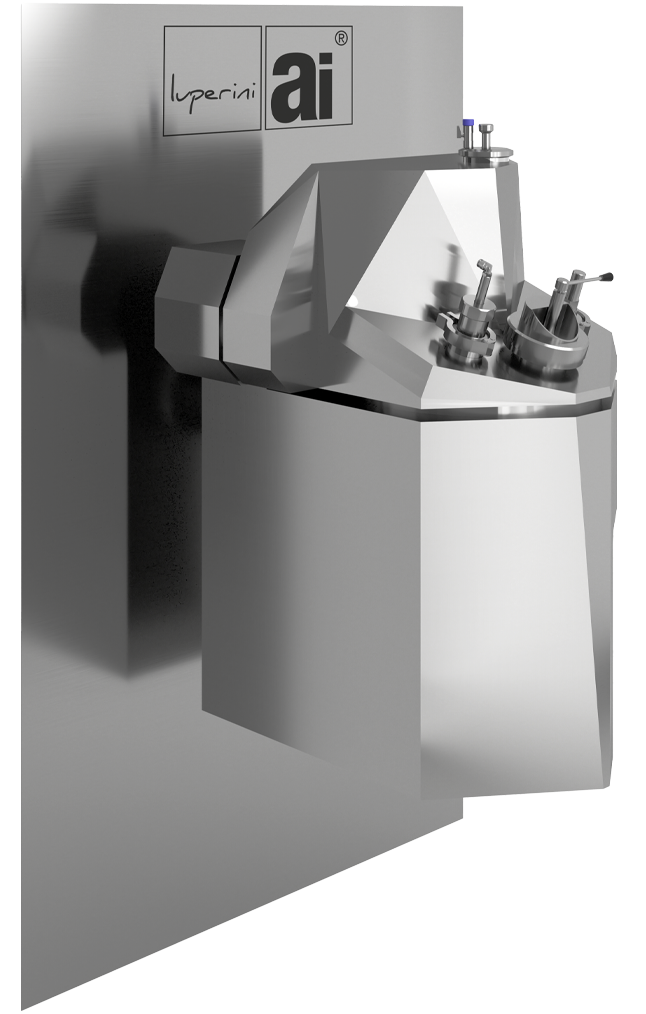

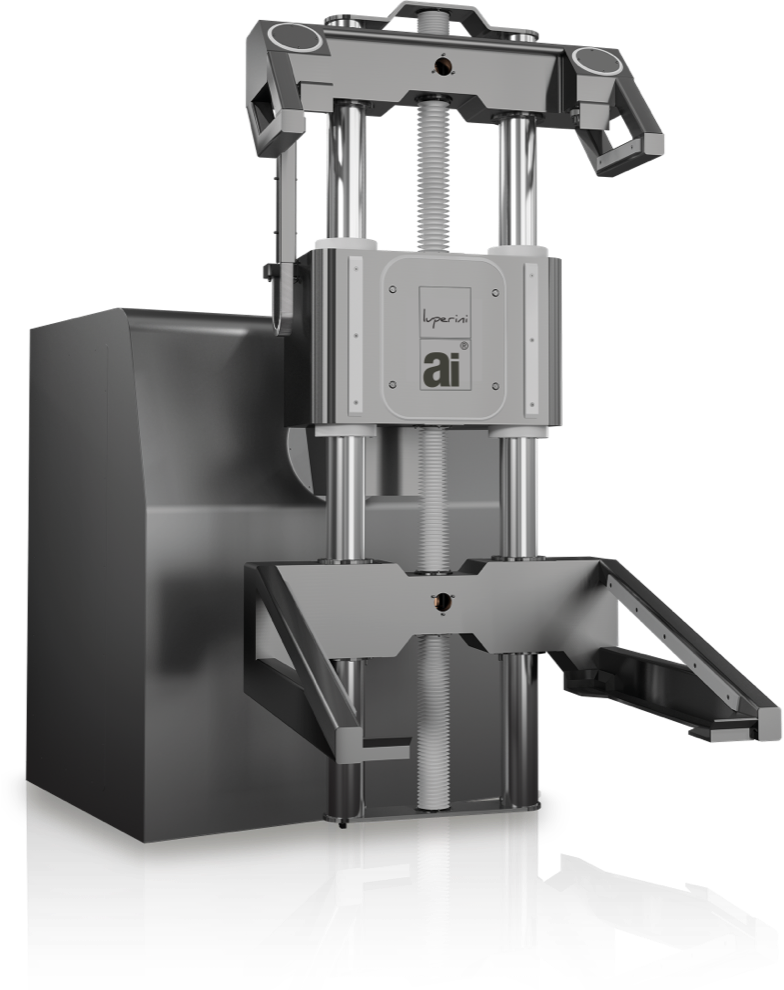

“Cognitive Pharma Machinery” line, which includes the new granulator H-POT (Haptic-Pot) and the blender A-TUMBLER (Autonomy-Tumbler), involves thirty years of experience in the design and manufacture of process machines, combined with the highest expression of control technology based on the application of artificial intelligence (AI) algorithms and neural networks.

The fusion of these elements has allowed Luperini to present a series of machines able to control the process dynamics, able to manage the variables in real time and able to make decisions independently, achieving zero tolerance and total efficiency in real time.

This technology allows the replication and optimization of each process, adapting the formula automatically in anticipation of the given endpoint, significantly reducing process time, costs, and waste.