Con el objetivo de continuar a DIFUNDIR LA CULTURA CIENTÍFICA SOBRE TECNOLOGÍAS Y PROCESOS FARMACÉUTICOS Luperini Pharma Machinery se enorgullece de lanzar su 2do CAPÍTULO en inglés de su sección “LUPERINI SCIENCE” dedicado a la granulación húmeda, escrito por nuestra experta la Profesora Erica Franceschinis.

Wet granulation

Several equipments are employed for wet granulation: low shear and high-shear granulators, and fluidized bed granulators are the most common in the pharmaceutical industry.

Low-shear mixers, such as planetary mixers and rotating drums, are simple technologies for granule production. The agglomerates produced by low shear mixers are characterised by a low density because of the limited energy exerted on the wet mass. On the other hand, high-shear mixers (HSMs) are characterised by high density as a result of the high energy applied to the granules.

HSMs are generally made up of a mixing bowl in which a main blade, called an impeller, and a second blade, called a chopper, are present. The main advantages of these equipments are the short granulation time and the lower amount of liquid binder necessary for the process. It is also possible to perform a single-pot process if the machine is equipped with a heating system (e.g. a heating jacket) and a vacuum system. The main disadvantage can be an excessive densification of the granules which can lead to a loss in tabletability.

In fluid bed equipment, an air stream promotes the fluidisation of powders while the liquid binder is sprayed through a nozzle on the moving powders. The use of a hot air stream produces drying of the granules. The granules produced using this technique are generally characterised by high porosity. The main advantages of this process are the narrow size distribution and flowing properties of resulting granules, the reduced overall process time due to the fact that all of the steps are performed on the same equipment, and high efficiency of the drying phase.

High-shear mixer (HSM)

High-shear wet granulation is a batch-wise process, and it is one of the most employed techniques in the pharmaceutical industries for size enlargement of powders.

The main advantages of high-shear wet granulation are:

- Efficient blending of the powder mixture, thus avoiding the need of an additional mixing step before the granulation;

- Short processing time;

- Lower amount of liquid required for granulation, thus reducing the drying phase and the energy required for solvent evaporation;

- The possibility to efficiently spread viscous binders among the granulating powders.

However, this technique presents some drawbacks which can limit its application like the production of dense granules which can lead to a loss of tabletability, and the numerous parameters which need to be controlled during the process make difficult the development and the scale-up of a formulation.

High-shear mixers can be divided in vertical axis and horizontal axis equipments; vertical axis HSM are the most employed in the pharmaceutical industries.

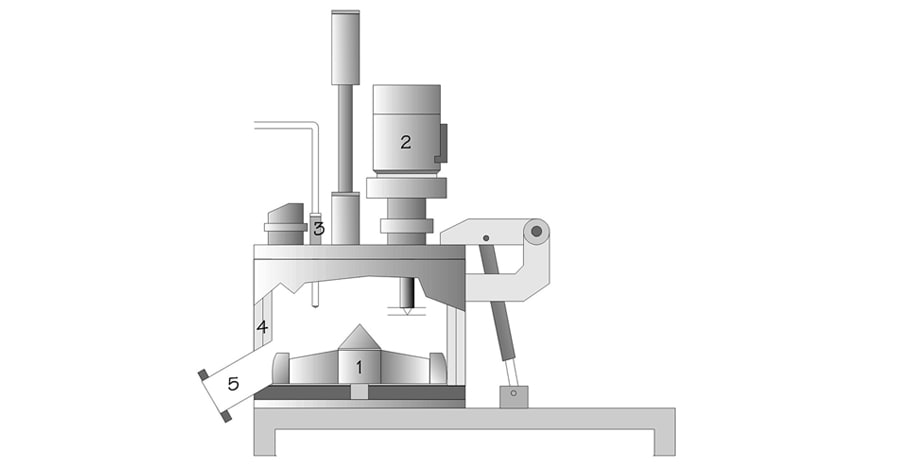

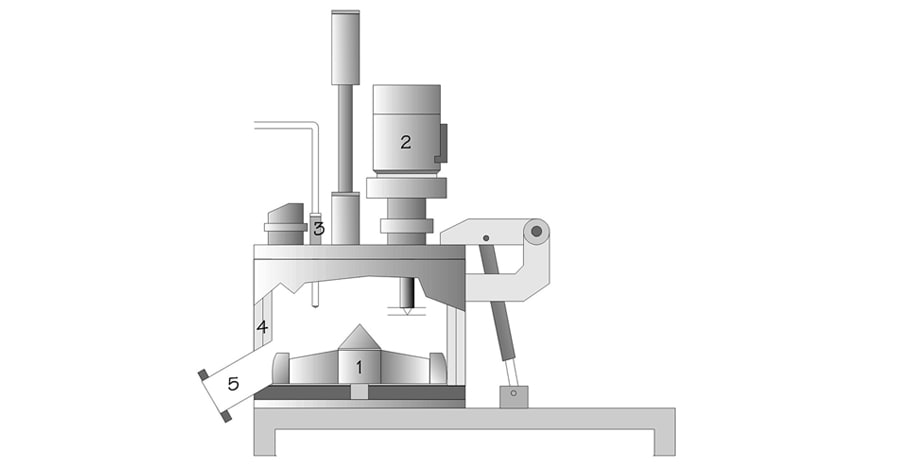

The typical layout of a vertical axis high-shear mixer is shown in Figure 1.

This equipment is composed of a mixing bowl in which two mixing tools are present: a main blade called impeller and a secondary blade called chopper. The impeller is generally a three-shaft blade that is assigned to mixing and fluidisation of the powders, homogeneous distribution of the granulating liquid, and vigorous agitation of the wet mass during the granulation phase. The secondary blade called chopper is characterized by a small size and a high rotational speed and its role is to break lumps which might form during the granulation process. The motion of the powder and granules in the HSM is of great importance for the final characteristics of the product because it drives the consolidation of the granules. In particular, for a successful granulation process, it is necessary to obtain a roping regime in which the powders follow a toroidal vortex motion. The roping regime allows an optimal mixing of the formulation components and a correct turnover of the powders during the liquid addition which can be successfully distributed. The critical impeller speed value to reach the roping regime can be influenced by the design of the impeller and the bowl, the powder properties and the operative conditions.

If the mixing bowl has a heating jacket, the equipment can be used to perform the melt granulation process. This feature can also be used to dry the granules at the end of wet granulation. In this case, a vacuum pump is applied to the granulator lid to remove the evaporating solvent. This application gives the possibility to use the HSM as a single pot equipment.

The granulating liquid is generally added using a nozzle placed on the lid of the HSM. The spray parameters, such the liquid flow and the drops diameter, are generally critical for the resulting granules characteristics.

If the mixing bowl has a heating jacket, the equipment can be used to perform the melt granulation process. This feature can also be used to dry the granules at the end of wet granulation. In this case, a vacuum pump is applied to the granulator lid to remove the evaporating solvent. This application gives the possibility to use the HSM as a single pot equipment.

The granulating liquid is generally added using a nozzle placed on the lid of the HSM. The spray parameters, such the liquid flow and the drops diameter, are generally critical for the resulting granules characteristics.

Steps of the high shear granulation process

The steps of the high shear granulation process are:

- Sieving and weighting of the powders.

- Loading of the powder mixture into the mixer bowl.

- Mixing of dry powders.

- Wetting phase: addition of granulating liquid on the powder mixture surface while it is fluidized by the impeller. The speed of the impeller is adjusted to have a homogeneous distribution of the liquid binder into the powder bed.

- Granulation or wet massing phase in which there is the formation and densification of the granules caused by the intense forces applied and the movement of the wet mass in the mixing bowl.

- Discharge: at the end of the massing phase, the impeller is turned off and the granules are discharged from the mixing bowl. Sometimes, prior to the drying phase, granules could be calibrated through a cone mill calibrator, which allows the breakage of oversized agglomerates and thus a better size uniformity.

- The drying phase can be performed in another equipment e.g. fluid bed dryer or oven. The drying of the granule can be performed also inside the HSM, in this case the granules are not discharged and the heating jacket and the vacuum pump are turn on (single pot process). Once the granules are dried, they could be calibrated through an oscillating sieving mill, which allows the reduction of lumps inside the final product, and thus a better size uniformity.

- Sieving of dry granules to select only those size fractions that are necessary for the following processes.