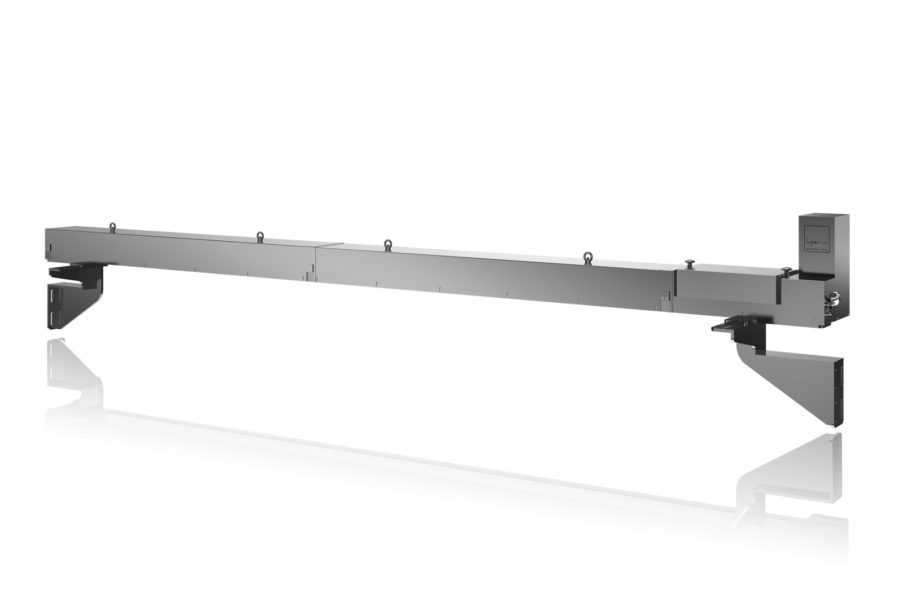

The Luperini size adjustment and tail cutting system consists of a structure containing high pressure pumps and an electrical panel, and a linear unit with a mobile carriage for the movement of the high pressure nozzle. The CutSled is designed to operate in a paper machine’s wet area, therefore its components can withstand high humidity conditions. The system’s control software allows the nozzle to move within the boundaries of the machine’s format, at distances and speeds that can be set from the control panel, both in manual and automatic mode. It is equipped with a self-braking motor with an integrated encoder and a belt transmission that ensures quick and extremely precise positioning.

Using the CutSled for automatic tail cutting provides for reduced downtime, optimised machine efficiency, and greater operator safety during the paper breakages.

The CutSled allows the paper size to be adjusted directly on the flat table, thus eliminating the need for trimming prior to entering the drying units. This preliminary operation eliminates the treatment of paper that will have to be trimmed at the end of the line, ensuring considerable savings in terms of energy, steam, starch, and treated scrap paper management.

Photo gallery

Advantages

- Water jet cutting

- Tail formation and full sheet enlargement

- Direct cutting on Canvas and Felt

- Quick, smooth and extremely precise nozzle movement

- Compact linear unit

- Linear unit from 1,000 mm to 14,000 mm

- Heat resistant belt transmission suitable for high humidity environments

- Linear unit extraction with the machine in motion

- Reduced maintenance

- Savings on energy, steam, starch and treated scrap paper management

- Increased production

Material specifications

- Sled support structure AISI 304 stainless steel

- External casing AISI 316L Stainless steel

- Aluminium sled

- Pump frame and electrical panel AISI 304 stainless steel