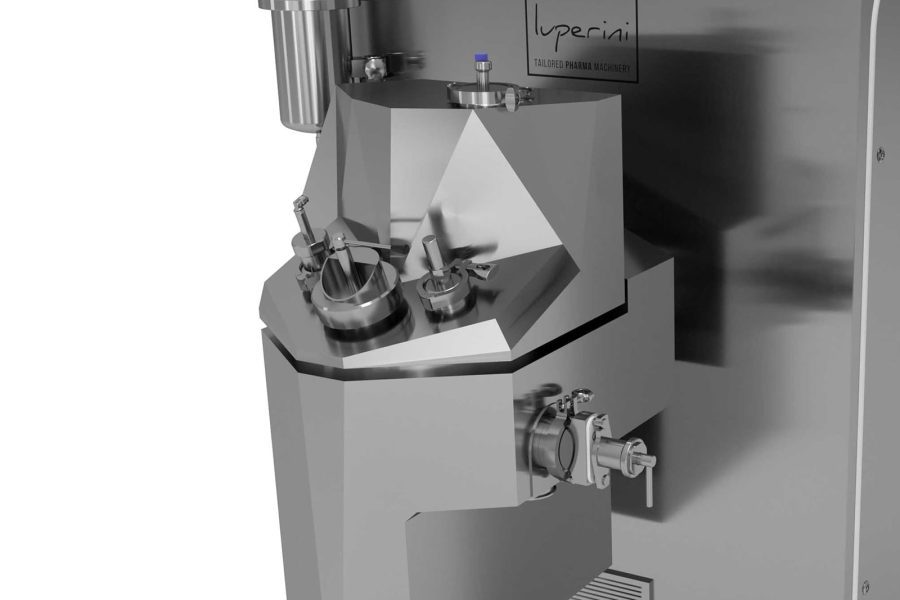

D-POT is a mixer, granulator and oscillating dryer “One Step” with high mechanical action (High Shear Mixer Granulator). Same as his peer I-POT, it can mix, granulate and dry pharmaceutical powders in different formulations, combining its blade and chopper movements. Thanks to the use of the vacuum group and heating group, it is possible to carry out the entire process in a single machine (ONE STEP) significantly reducing the risk of product contamination, reducing product loss (that can be generated during powder transfer from the granulator to an FBD) and reducing complete process time.

Drying time is now significantly reduced, a feature that was improved thanks to the use of oscillation (Tilting) that homogeneously distribute the product on the hot sides of the machine.

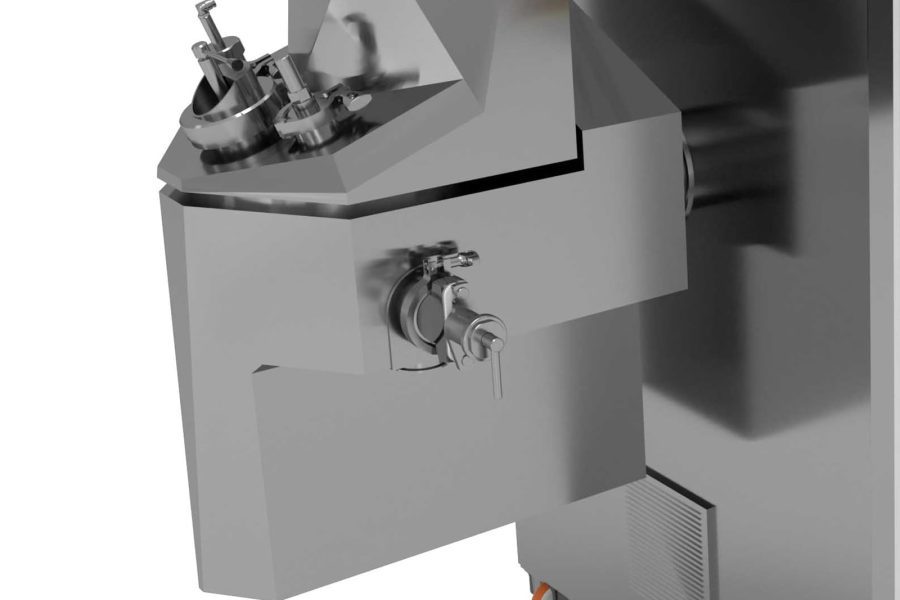

The use of the discharge Clapet valve (an optional), combined with that oscillation favors product flow during discharge phase. This factor privileges the efficiency of the machine by reducing product cycle time and product loss.

The new design was studied to make D-POT completely hermetic, thus ensuring the possibility of processing any type of product, from hormones to anticancer, oral contraceptives, effervescent, etc. etc.

Outstanding feature: its external shape recalls the facets of a diamond and turns D-POT into a unique machine of its kind.

- Container Oscillation System to increase the surface available for heat exchange during product drying phase. The oscillation also prevents adhesion of the product, significantly reducing drying time.

- Telescopic chopper adjustable in the various product ranges. Really useful when the D-POT needs to run processes with product load below its maximum.

- Easily removable filter unit with possibility of extracting every single cartridge for filter sleeves replacement, the extraction is fast and simple.

- Vacuum product loading system.

It is possible to install high containment loading and unloading system. - GMP design. Thanks to CNC machining, the buffer profile matches perfectly with that of the container, improving sealing performance, facilitating product discharge and evacuation of the washing liquid.

- Its 3-spoke bottom blade with special design angles, generates a very high thrust, creating a specific mixing action and an excellent mechanical action on the product.

- I-Cone Mill, when it is integrated into the D-POT structure, allows to calibrate dry or wet products in line. This configuration let the granules be quickly and directly processed, calibration is controlled directly from the D-POT control panel. I-Cone Mill can be CIP or WIP washing in-line, (also controlled by the D-POT control panel).

Photo gallery

Control system

D-POTCONTROL is designed to navigate to various software pages in a simple and intuitive way, allowing to control diverse parameters such as; speed, data temperature, recipes, alarms, messages etc.

Its interface consents to view and control the entire machine process, from product loading to washing. It is possible to perform diagnosis and verification of the machine in remote assistance.

The software follows the guidelines in accordance with CFR 21 Part 11.

Related products

Auxiliary units

Heating/cooling skid for controlled product drying process.

Vacuum units sized and designed to obtain different performance: from the vacuum necessary only for product loading to high vacuum for “difficult” processes.

Dettails

- Based on a scale-up, configurations and options best suited to each specific process are available.

Equipped with automatic systems for product loading by gravity through our I-PHARMA BIN, or through a vacuum loading system (in high containment using special valves). - Binding solution spraying system, manual or automatic version.

- D-POT is a granulator with oscillation system, heated jacket and hot air introduction through its bottom blade, that allows to process difficult products, obtain better quality granules and reduce drying process time.

- It is possible to discharge the product directly into an I-PHARMA BIN, or calibrate the product in line through Luperini’s I-CONE MILL calibrator (it can be done also in high containment, using special valves).

- D-POT can be easily cleaned using WIP or CIP systems at the end of each cycle, and can be entirely inspected, facilitating FDA validation.

- D-POT can process wet (with water) products or solvents and can recover all the steam through an integrated condensation system

- Flexible technology: processing of effervescent products, sensitive to heat and humidity

- Reduce spaces, wall installation (through wall).

- D-POTCOTROLL, control system with industrial touch screen PC, 21 CFR PART 11 for process control and supervision, automatic or manual.

- Upon request D-POT is available in ATEX version, to operate in hazardous areas