E-TUMBLER mixers series point at different types of industries that intend to mix IBCs with the highest quality in a cost-effective way.

E-TUMBLER originates from its “older brother” I-TUMBLER, and so It keeps its IBC mixing top quality characteristics unaltered. This peculiarity is due to its combined inclinations, obtained through specific CNC machining, which results in an asymmetrical high efficiency mixing blend.

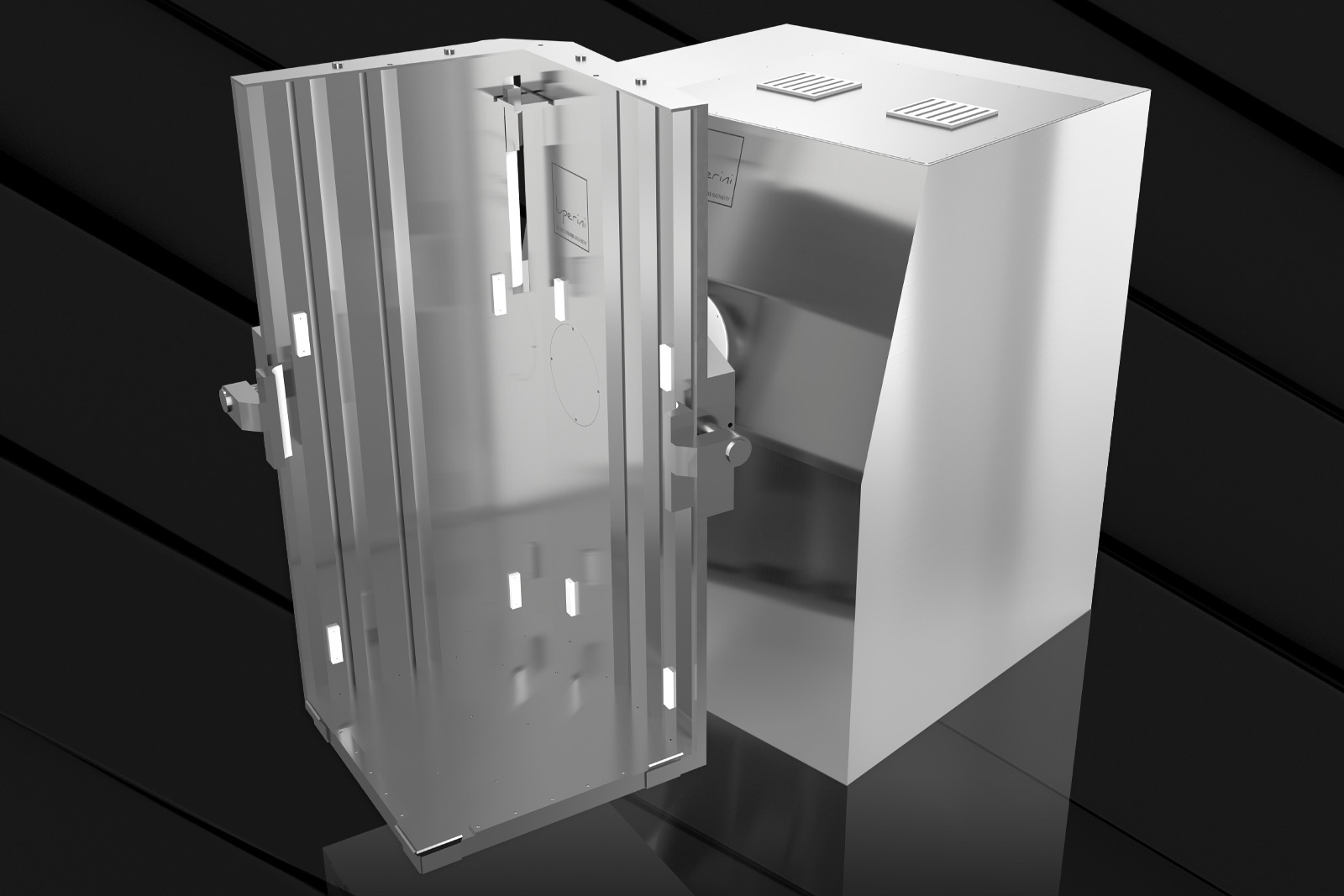

E-TUMBLER is composed of a supporting structure containing its gearmotor and transmission shaft, built and covered in sandblasted carbon steel and subsequently painted. The electrical panel is separated from the structure and can be placed in a dedicated area. The Bin container structure can be supplied in painted carbon steel or in stainless steel 304.

E-TUMBLER can mix 900 x 900 and 1200 x 1200 Bin containers, from 50Lts to 2200Lts.

Photo gallery

Security features

- 3-point container locking system

- Security check of the position of the arms

- Lower centering cups

Optional

- Diverse machine parts materials to choose from (painted carbon steel, stainless steel etc.)

- Possibility of installing NIR probes for monitoring the production process

- Possibility of installing the E-TUMBLER on the wall (Through wall) to reduce the overall dimensions and optimize process area space.

Benefits

- Designed to operate in environments where the use of stainless steel is not a binding factor

- Cost-effective

- Mixing Maximum safety

- Robust and efficient

- Possibility of “Through wall”/Wall-mounted installation

- Simple and intuitive operator interface

- Save and manage mixing recipes

- 21 CFR Part 11 Compliance

- Validation according to GAMP standards