The I-Vibrating Sieve is available with a single or multi-stage body, and sieves of various sizes and diameters. It comes as a stand-alone solution mounted on wheels, with a built-in control panel.

High containment loading and unloading systems with disposable containment solutions.

Possibility of modulating the frequency to adjust the vibration as needed.

Standard or custom connections available for both product intake and discharge.

Various components and accessories are available in our catalogue for use in the pharmaceutical, fine chemical and food industries.

We are able to customise our products and design new ones based on specific requirements.

Photo gallery

Related products

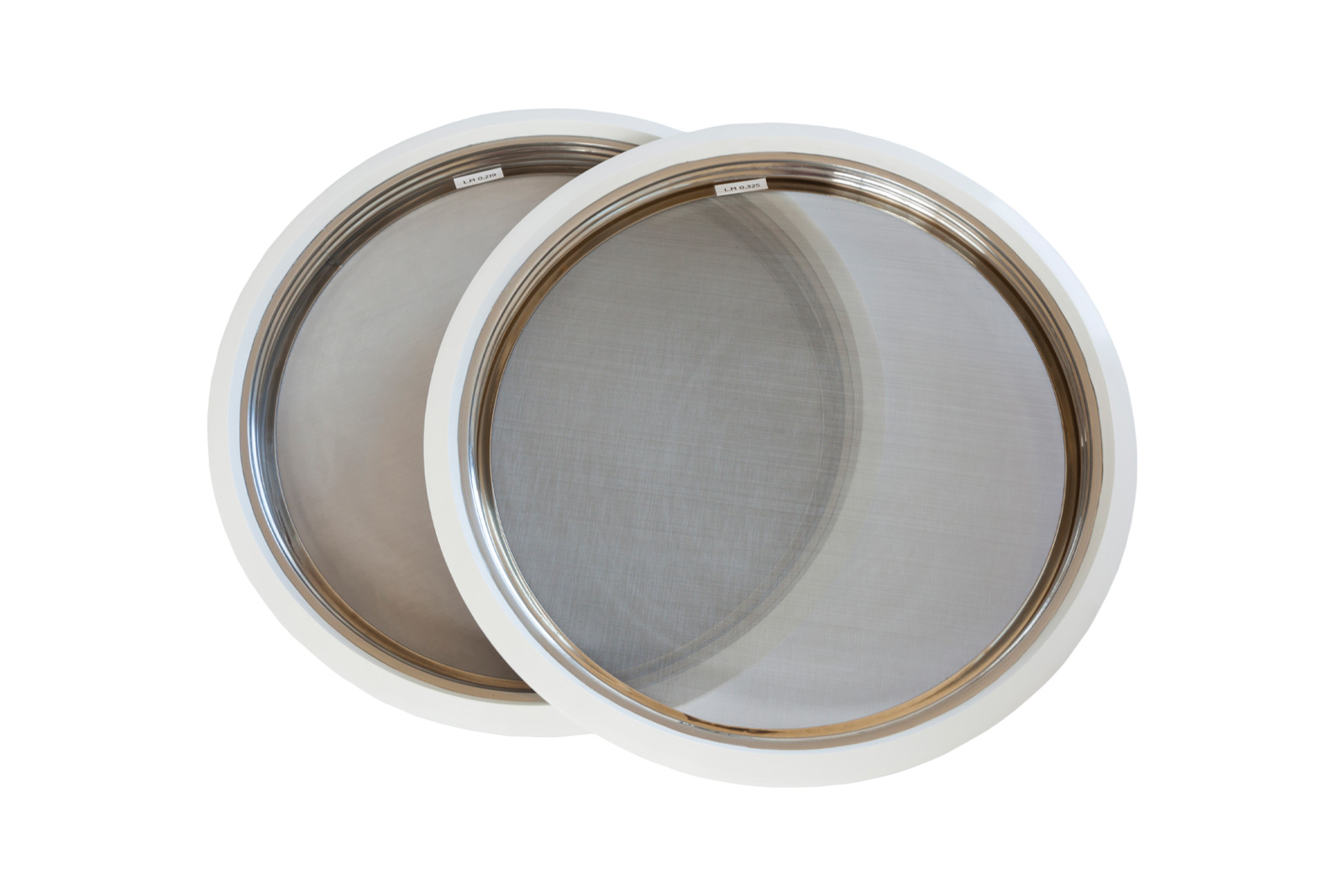

GMP-compliant silicone seals vulcanised and incorporated directly into the mesh holder frame (sieve).

Drain in high containment version

Advantages

- Modular system

- High productivity

- Ease of disassembly and cleaning

- Stand alone solution

- Durable and reliable.

Material specifications

PARTS IN CONTACT with the product made of certified AISI 316L stainless steel:

- Glossy internal finish, Ra 0.5 micrometers.

- Internal welds smoothed and polished to a Ra of 0.5 micrometers.

NON-CONTACT PARTS:

- Welds smoothed and ground to a Scotch-Brite finish.

- Parts not in contact with the product made of AISI 304 stainless steel.