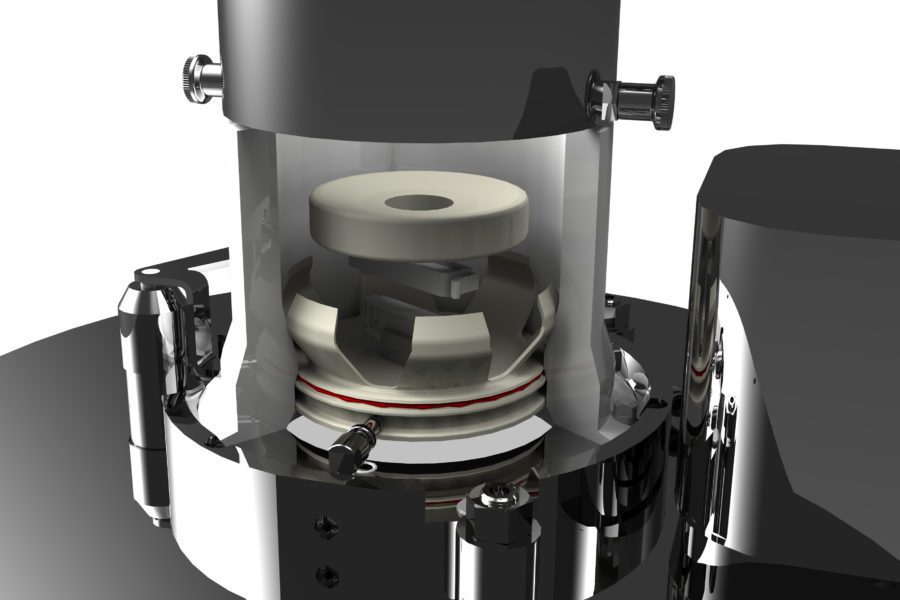

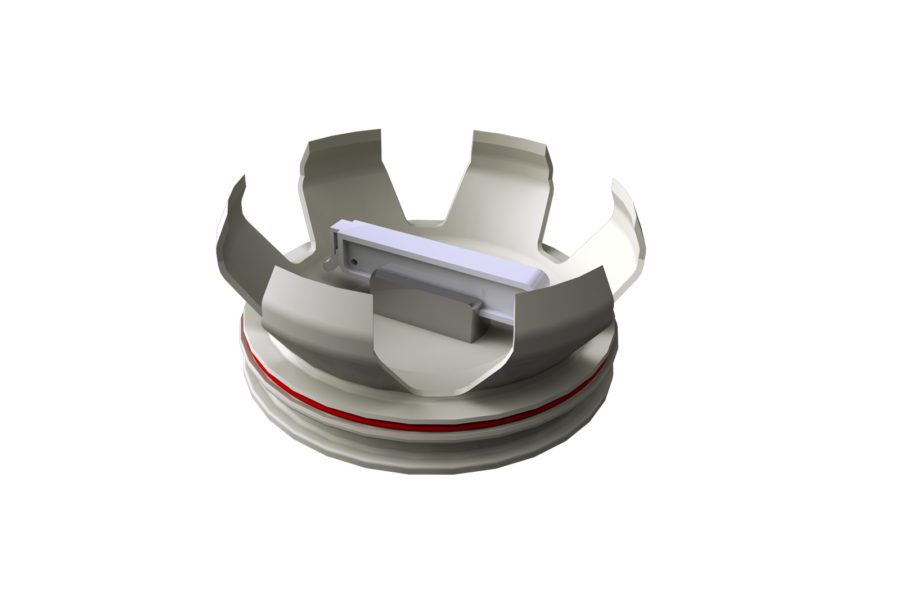

A high-containment unloading system with certified disposable polyethylene liner, suitable for gravity unloading from a station located on the upper floor to a machine located on a lower floor. This high containment system is fully automatic and built according to the GMP standards.

The innovative magnetic system for moving the cartridge and the liner allows the different areas to be maintained separate, thus eliminating the risk of product contamination. The tube and external casing are made from transparent polycarbonate to allow for the visual monitoring of the process and quick inspections. The easy-to-install modular system does not need any external units, and does not require the use of flexible pipes.

Photo gallery

Related products

Options

- Simple conversion of the existing Bin attachment system.

- No interaction between the technical area and the process area.

- No disassembly and cleaning operations.

- Controlled transport of the falling product to eliminate the possibility of de-mixing