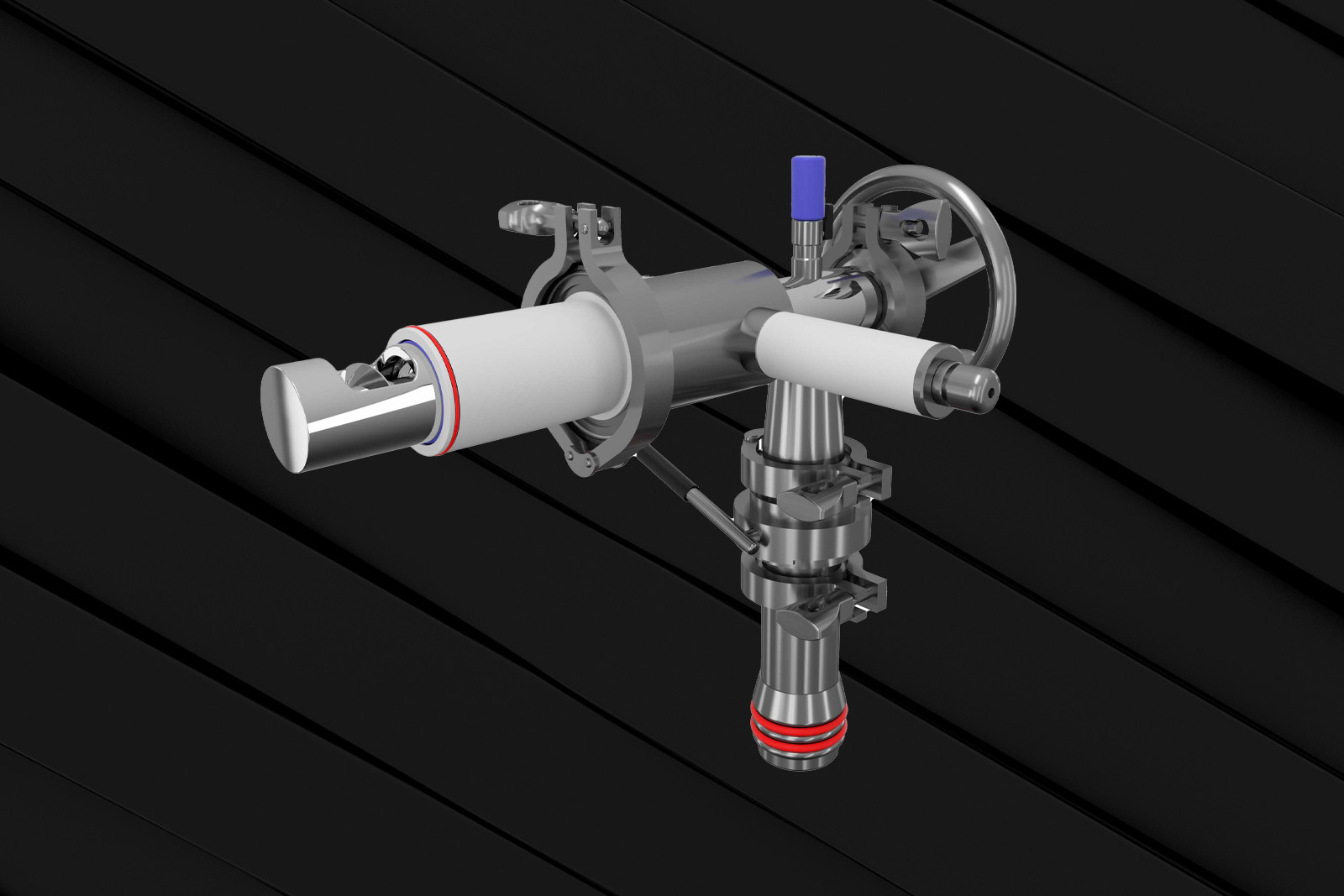

Manual product sampling probe. Possibility of integrating the I-Capture M with I-POT series granulators (High Shear Mixer Granulators), or other Luperini machines and equipment.

I-CAPTURE M

Manual sampling probe, designed and built to be easily disassembled and to facilitate cleaning and washing operations.

In the case of installation on the I-POT, the sampling cycle can be carried out at any stage of the process, even with vacuum inside the machine.

Various components and accessories are available in our catalogue for use in the pharmaceutical, fine chemical and food industries.

We are able to customise our products and design new ones based on specific requirements.

Related products

Advantages

- High containment sampling.

- Possibility of performing sampling at any stage of the process, even in the presence of a vacuum.

- Ease of installation and disassembly to facilitate cleaning and washing.

- Durable and reliable.

Material specifications

PARTS IN CONTACT with the product made of certified AISI 316L stainless steel and Polymers:

- Glossy internal finish, Ra 0.5 micrometers.

- Internal welds smoothed and polished to a Ra of 0.5 micrometers.

NON-CONTACT PARTS:

- Welds smoothed and ground to a Scotch-Brite finish.

- Parts not in contact with the product made of AISI 304 stainless steel.